About ceramics

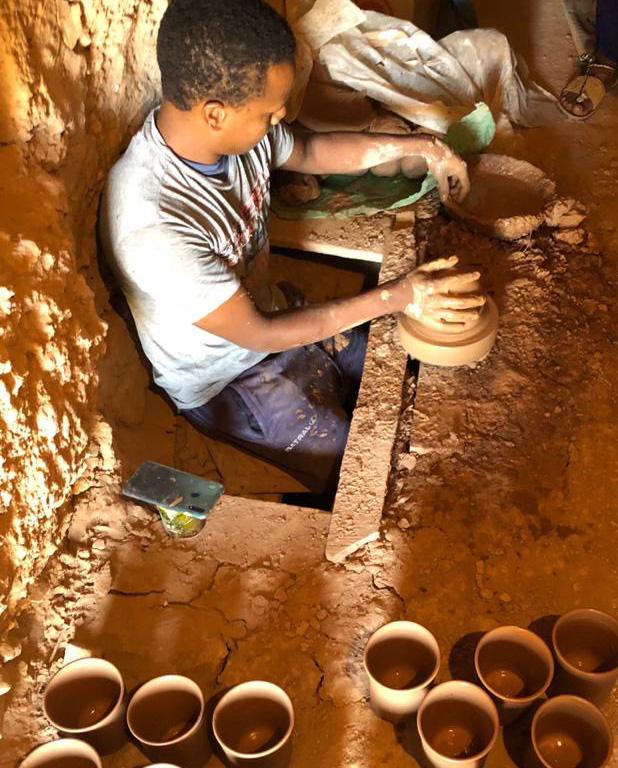

The ceramics shown here is made by Atman and his team. The green color is characteristic for the city of Tamagroute.

Producing earthen work is a time consuming process. First, clay has to be dug up from the river, about 3 kilometers away from Atmans workshop. Then the clay is smashed to a smooth and equal mass.

The next step is pouring the smashed clay with water. The mixture is kept in a hole in the ground for a couple of hours. The by then soft clay is spread out on the ground, as shown below. Smaller bits are taken off for easier processing.

Completely by hand the pots, pans and tajines are shaped in model.

When finished, the items need to dry in the shadow for a full day, followed by a week of drying in the sun. This order is to ensure the moulded items won’t break.

After the drying process, the painting takes place. In order to get the characteristic green color, a mixture of manganese, silicium and copper oxide is added, together with a saltless oatmeal porridge. The earthen work will turn gray.

These grey half products are then baked in ovens outside the premises, where temperatures rise up to 1200 degrees Celsius. To heat the ovens, wood of the acacia tree is used. Slowly the grey color will make place for the recognizable green.

The distinct yellow color is the result of manganese, silicium and the saltless oatmeal porridge.

As shown, Atman and his team make everything by hand. This means that custom made orders are possible. Inquire for the possibilities.

Below you can see what Houssaine has made for you and what you can buy now.

Showing 40–42 of 108 resultsSorted by latest